INTRODUCTION PDF

The terracotta from antiquity to today has always had a great variety of uses, thanks to its resistance and the fact that it can be considered a "living" material that breathes. At present, it is experiencing a second youth, above all as a flooring material: it can safely be said that most of the new buildings and renovations at least part of the terracotta flooring. And it is precisely one of its most valuable features, namely the fact that it is a porous and breathing material, which creates the biggest drawbacks to those who want to enjoy its beauty and warmth.

It is in fact a material that easily absorbs drops of oil, wine and sauces. It is a material that remains perpetually stained even by a simple trampled cigarette butt.

To avoid this problem, the installers and producers of terracotta materials have always recommended the traditional treatment with linseed oil. It involves spreading raw linen oil on the already well-cleaned and brushed terracotta. Linseed oil is difficult to spread; it can present at the end of the work of flaming and streaks and above all it maintains a residual permeability that doesn’t preserve the floor from all possible staining products.

In addition to linseed oil, a special wax treatment is required. There are some very precise times and methods to be followed and these are non-definitive treatments, but they must be repeated periodically as the products applied over time deteriorate, evaporate or otherwise lose their effectiveness. Lately we have witnessed the placing on the market of numerous synthetic products, which would have had to definitively solve the problem by waterproofing the floor and thus eliminating the treatment with linseed oil. The results for many of these products were not exceptional.

Plasticizers are found that perform their task well, but which present a significant application difficulty and in any case the intervention of skilled labor.

Other products on the market form an absolutely waterproof film and consequently require that in the terracotta tiles there is not the slightest residual humidity. Considering that this is a practically unrealizable condition, after a while, the detachment of the film will take place with the results that we can all imagine.

It was the resolution of these problems that guided our research to arrive at the formulation of the product

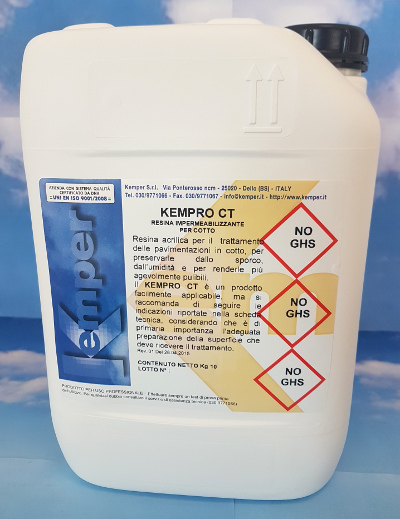

KEMPRO CT

acrylic resin for the treatment of terracotta

Ease of application. The KEMPRO CT can be applied by anyone, using a normal big brush, or a roller.

Automatic dosing. It is not necessary to perform complex and mostly arbitrary calculations: the floor itself will reject the excess product.

Duration. A terracotta floor requires only one treatment. No refreshments or further applications are necessary until after several years.

Full resistance. Excluding naturally some types of special solvents, which on the other hand we would find only in laboratories and chemical industries, it can be said that the treatment with KEMPRO CT resists practically everything.

HOW TO APPLY THE KEMPRO CT

The methods and times are very important. It is easy, for too much haste to make work useless and above all ruin a beautiful floor irremediably.

1) It is advisable to start the treatment at least 30-40 days after laying the tiles. In this period, which in the winter months will have to be almost doubled, it will be convenient to ventilate the premises well to allow to eliminate as much humidity as possible.

2) A very important phase concerns the cleaning of the floor. After a preliminary cleaning with a broom, as long as possible to remove the largest amount of debris, it is recommended to wash with a 20% solution of FLOOR C. Pour the solution on the floor, after having abundantly wet it, rub it with a scrub brush and leave to act for 10-15 minutes. You return to brush with a mop and, on the joints, with a steel brush.

It is very important, once the descaling is complete, proceed to a generous rinsing with clean water to remove the dirt and residues of the detergent. The best results are obtained, in this phase, using a wet vacuum cleaner which allows to obtain good results in a short time. The complete elimination of incrustations and efflorescences will be noted only on dry floors. It will therefore be necessary to wait for the drying before deciding whether to go to the next step or if to repeat the cleaning.

In some cases the whitish efflorescences reappear even after 10-15 days and it would therefore be advisable to wait for this period before proceeding with the laying of the resin.

3) Spreading of the resin. It is perhaps the simplest operation since it provides a large brush or even a short-haired roller as a tool; as an operation nothing but the most uniformly possible draft of the KEMPRO CT on the floor, bearing in mind to apply the least possible quantity: even with very porous material, 30-40 grams of product per square meter must be sufficient.

Also make sure that no streaks or droplets remain, which, once the resin has dried, will appear whitish and not transparent.

The absorption of this first coat of product will be practically immediate, so, after finishing a room, it will already be possible to resume work to apply the second coat. Only in the winter months will it be necessary to wait a few hours and in any case the thing will be highlighted by the same state of the floor that will present "dry". Always with the same criteria it will be evaluate if necessary apply a third coat. The most important thing to keep in mind is that when the floor is treated in the right measure, it will simply be detected by the fact that the tiles don’t "receive" more other product. During all this operation the quantity of product that is used doesn’t generally exceed 100-120 grams per m2. Considering the innumerable quality of terracotta currently on the market it is unfortunately not possible to be more precise: you can obtain excellent results already with 50 grams of product per meter on a certain type of floor and can be just 100 grams on another.

The complete treatment at this point is finished and as soon as the floor is dry it can be safely used.

MAINTENANCE

For normal floor maintenance it will then be sufficient to use a cloth soaked in FLOOR WAX, diluted (3 glasses of wax in 5 liters of water) and if necessary, on a dry floor, pass the polisher.

In the case of stains and stubborn dirt, it is possible to wash with a good floor cleaner (FLOOR N, FLOOR B).

Treatment with KEMPRO CT is essentially valid for interiors, but can also be used outdoors. With regard to these floorings, however, we believe it is necessary to draw attention to the fact that the descaling treatment can never be considered definitive, since humidity infiltrations, which then carry the salts to the surface, are evidently much more frequent and probable and therefore will be it is necessary to provide for the repetition of the treatment at least every two years.

A partial solution of the problem could be to waterproof the back of the tiles before laying and to use for the grout a mortar prepared with a solution of water and 3% ARAM.